The Industrial Ai Transformation Guide Manufacturing

Most industrial AI initiatives are failing spectacularly, and leadership teams are celebrating anyway.

Most industrial AI initiatives are failing spectacularly, and leadership teams are celebrating anyway.

What if I told you that despite the breathless headlines about AI revolutionizing manufacturing, up to 85% of industrial AI projects never make it past the pilot phase? The manufacturing sector is littered with the corpses of promising AI initiatives that consumed millions in investment before quietly disappearing.

Here's what's fascinating: the problem isn't the technology. In my experience working with dozens of manufacturing leaders across multiple continents, the technology is actually the easy part. The hard part? Everything else.

The manufacturers who are genuinely transforming their operations with AI aren't doing it by chasing the shiniest algorithms or hiring the most PhDs. They're succeeding because they've recognized that industrial AI transformation is fundamentally a business and organizational challenge masquerading as a technical one.

Let's explore what's really happening beneath the surface of industrial AI transformation - and why the conventional wisdom about how to implement it is almost entirely wrong.

The Real Challenge: It's Not What You Think

Fig. 1: Visual representation of industrial AI transformation methodology and workflow

When manufacturing leaders come to us, they typically frame their AI challenges in technical terms: "We need better predictive maintenance" or "We want to optimize our production scheduling."

But here's the critical insight that changes everything: the most significant barriers to industrial AI transformation are rarely technical.

What about your specific situation? Have you found yourself focusing on algorithms and data science talent while your AI projects struggle to gain traction? You're not alone. The underlying issues typically revolve around organizational readiness, data infrastructure, and alignment between AI initiatives and business priorities.

The Uncomfortable Truth About Industrial AI Projects

Fig. 2: Advanced analytics for industrial AI transformation monitoring and optimization

Most people believe successful industrial AI transformation requires cutting-edge algorithms and massive datasets. But the reality is that the algorithm isn't the hard part. The data is.

Let's challenge some conventional wisdom with data:

- While 87% of manufacturers are investing in AI initiatives, 76% struggle with ROI measurement, essentially flying blind on whether their AI investments are creating value.

- The majority of manufacturers focus their metrics on technical success (model accuracy, etc.) rather than business impact.

- Companies that establish clear business value metrics before implementation are 3.5x more likely to scale AI successfully.

In our work with a major automotive components manufacturer, we discovered they had invested over $4 million in an AI-driven quality inspection system that achieved impressive technical metrics but had zero measurable impact on actual defect rates or customer satisfaction.

This disconnect between technical success and business impact isn't unusual – it's the norm. And it explains why so many industrial AI initiatives fail to scale despite "successful" pilots.

The Industrial AI Transformation Framework That Actually Works

Fig. 3: Comprehensive architecture supporting industrial AI transformation implementation

If you're serious about transforming your manufacturing operations with AI, you need a framework that addresses the real challenges. Here's what we've found works consistently:

1. Start with Value, Not Technology

Begin by identifying specific business problems where AI can create measurable value. This seems obvious, but it's astonishing how many companies start with "we need to implement AI" rather than "we need to solve this specific business problem."

Key action: Create a value map that identifies high-impact areas where AI can address existing pain points. Prioritize based on potential ROI, not technological sophistication.

2. Build Your Data Foundation

Before you hire a team of data scientists, ensure you have the data infrastructure to support AI initiatives. This includes:

- Data accessibility: Can you actually access the data you need?

- Data quality: Is the data accurate and complete enough?

- Data integration: Can you connect data across different systems?

- Data governance: Do you have clear ownership and policies?

Key action: Conduct a data readiness assessment for each potential AI use case.

3. Create Cross-Functional Teams

Industrial AI transformation fails when it's treated as an IT or engineering initiative. Success requires cross-functional teams that include:

- Operations experts who understand the processes

- IT specialists who understand the systems

- Business leaders who understand the strategic priorities

- Data specialists who understand how to work with the data

Key action: Establish AI pods with representatives from each key function, empowered to make decisions and drive implementation.

4. Implement Multi-Dimensional ROI Measurement

This is where 76% of manufacturers struggle. Effective ROI measurement for industrial AI must consider:

- Direct financial impact (cost savings, revenue increases)

- Operational improvements (efficiency gains, quality improvements)

- Strategic advantages (competitive positioning, new capabilities)

- Organizational learning (knowledge transfer, capability building)

Key action: Develop a balanced scorecard for AI initiatives that captures both immediate and long-term value creation.

5. Scale Through Systematic Knowledge Transfer

The most successful manufacturers don't just implement AI solutions; they build internal capabilities that allow them to scale those solutions across the organization.

Key action: Create internal knowledge-sharing mechanisms and training programs to spread AI capabilities throughout the organization.

Real-World Implementation: What Actually Happens

Let's look at how this framework plays out in practice:

A global chemical manufacturer we worked with was struggling with yield optimization across multiple plants. Previous AI initiatives had produced impressive models that operators ignored because they didn't trust the recommendations.

By applying our framework, we:

- Started by quantifying the business value of a 1% yield improvement ($3.2M annually)

- Built a data foundation that integrated process data, quality data, and operator logs

- Created cross-functional teams including operators, process engineers, and data scientists

- Implemented a multi-dimensional ROI measurement system that tracked not just yield improvements but also operator adoption and knowledge transfer

- Scaled through systematic training and capability building

The results? A $23M annual value creation through not just yield improvements but also reduced quality deviations, lower energy consumption, and faster new product introductions.

What made this successful wasn't the sophistication of the algorithms. It was the focus on business value, operator trust, and organizational capability building.

The Technical Depth That Actually Matters

While the framework above addresses the organizational aspects of industrial AI transformation, there are technical considerations that are critically important:

Data Architecture for Industrial AI

Most manufacturing environments weren't designed with AI in mind. Their data architectures typically feature:

- Siloed operational technology (OT) and information technology (IT) systems

- Inconsistent data formats and naming conventions

- Limited historical data storage

- Real-time data streams that aren't captured or stored

Creating an effective data architecture for industrial AI requires:

- Edge-to-cloud integration: Processing some data at the edge while sending other data to the cloud

- Data lakes/data warehouses: Centralized repositories that can handle structured and unstructured data

- Data pipelines: Automated processes for extracting, transforming, and loading data

- Master data management: Ensuring consistency across systems

The AI Applications That Create Real Value

In our experience, these are the industrial AI applications that consistently deliver value:

- Predictive quality: Identifying potential quality issues before they occur

- Process optimization: Continuously adjusting parameters to maximize yield and efficiency

- Predictive maintenance: Determining when equipment is likely to fail

- Supply chain optimization: Improving forecasting and logistics

- Energy optimization: Reducing energy consumption while maintaining production

The technical implementation of these applications varies widely based on your specific processes and data environment. But the common thread is that they all directly impact operational and financial metrics that matter to the business.

The Future of Industrial AI Transformation

As we look ahead, several trends will shape industrial AI transformation:

- The convergence of IT and OT: The traditional separation between operational technology and information technology is disappearing.

- Edge AI: More processing will happen at the edge, reducing latency and bandwidth requirements.

- Human-AI collaboration: The most effective implementations will focus on augmenting human capabilities rather than replacing them.

- Ecosystem approaches: Manufacturers will increasingly collaborate with suppliers and customers on AI initiatives.

What does this mean for manufacturing leaders? The competitive advantage will go to those who can build organizational capabilities around AI, not just implement specific solutions.

Where Do You Go From Here?

Industrial AI transformation isn't easy, but it's also not as mysterious as many make it out to be. The path forward requires honest assessment and strategic action.

Ask yourself:

- Are your AI initiatives aligned with clear business objectives?

- Have you built the data foundation necessary for success?

- Do you have the cross-functional teams needed to drive implementation?

- Are you measuring ROI in ways that capture the full value of AI?

- Do you have a plan for building organizational capabilities, not just implementing solutions?

The manufacturers who are truly transforming their operations with AI aren't necessarily the ones with the biggest budgets or the most advanced technology. They're the ones who recognize that industrial AI transformation is fundamentally about changing how the organization works, makes decisions, and creates value.

What could your manufacturing operation achieve if you approached AI transformation as a business challenge rather than a technical one? The answer might surprise you.

Ready to start your industrial AI transformation journey? Begin with a value mapping exercise to identify where AI can create the most significant impact for your specific operations. The technology will follow.

Sources and References

-

PwC Digital Factory Survey Credible industry research and analysis

-

McKinsey Smart Factory Report Credible industry research and analysis

-

MIT Technology Review Industrial AI Credible industry research and analysis

-

Deloitte Industry 4.0 Study Credible industry research and analysis

-

Boston Consulting Group Manufacturing Research Credible industry research and analysis

Related articles

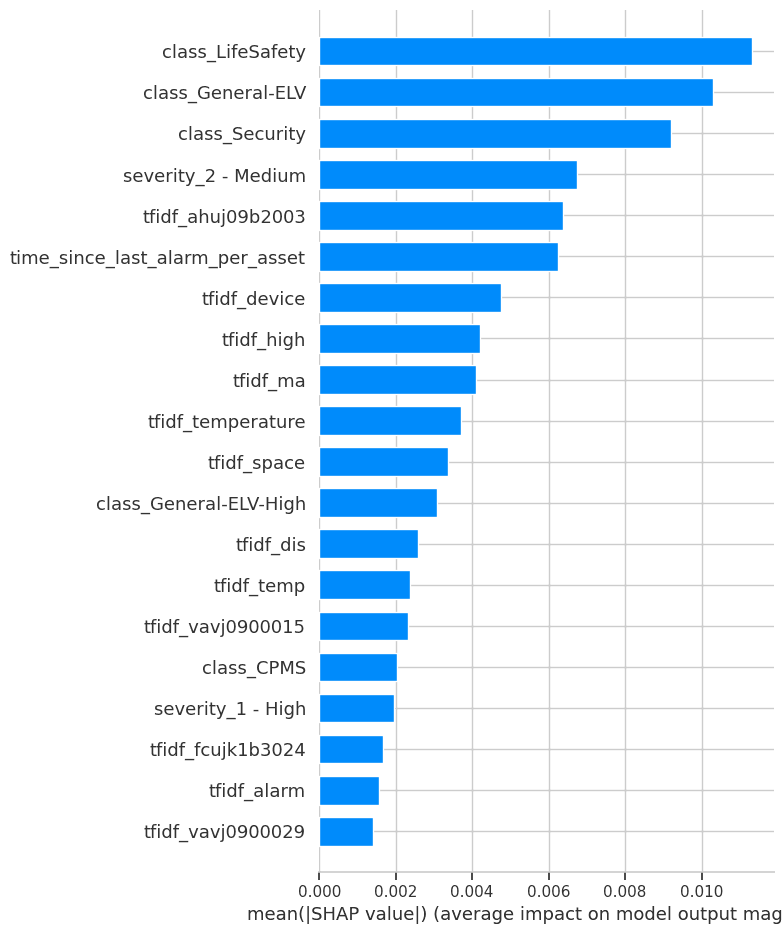

Project Report: Symptomatic Alarm Pattern Discovery and Root Cause Analysis

A formal summary of Project ID a496e3ae-5149-4a15-86dd-a3aee47f493f. This report details the full execution of the project, from the analysis of 102,319 alarm records to the development of an analytical pipeline for anomaly detection and the strategic vision for future capabilities.

From Data to Decision in Seconds: The Autonomous Engine for Industrial Excellence

You're data-rich, but knowledge-poor. The gap between possessing data and possessing actionable knowledge—Decision Latency—is the defining operational challenge of our time, and the key to unlocking your next wave of growth.

Ready to get started with ML4Industry?

Discover how our machine learning solutions can help your business decode complex machine data and improve operational efficiency.

Get in touch