Smart Manufacturing best practices: Framework for production facilities

Smart Manufacturing: Why Your Framework Is Probably Backwards. Think you've got a solid smart manufacturing strategy?

Smart Manufacturing: Why Your Framework Is Probably Backwards

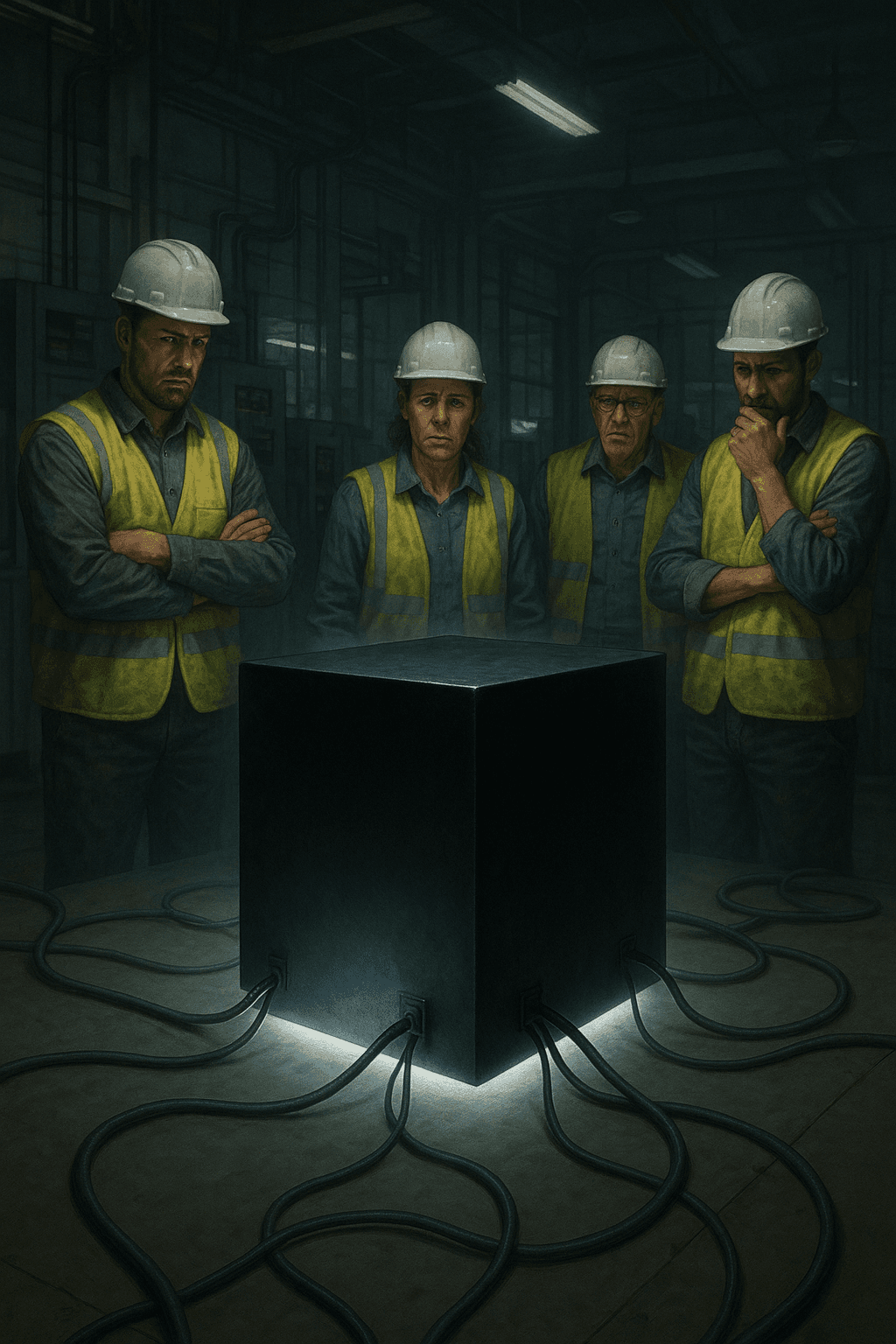

Think you've got a solid smart manufacturing strategy? I've spent the last decade working with factory automation systems, and I've noticed something surprising: most production facilities are implementing smart automation in exactly the wrong order. We tend to chase the shiniest new technologies while overlooking the foundational elements that actually drive sustainable transformation.

Here's what's crazy: according to recent industry data, nearly 70% of smart manufacturing initiatives fail to deliver their expected value. Not because the technology doesn't work, but because the implementation framework is fundamentally flawed. The problem isn't the tools—it's how we're approaching them.

The Backwards Approach to Factory Automation

When I visit manufacturing facilities eager to modernize, I typically see the same pattern. Leadership gets excited about advanced robotics, AI-powered analytics, or digital twins, investing millions in these technologies before establishing the proper foundation. It's like building a high-tech house on sand—impressive at first glance, but ultimately unsustainable.

What if I told you that the most successful smart factories don't start with cutting-edge technology at all? The reality is counterintuitive: they begin with people, processes, and basic data infrastructure.

Let me share a framework that flips conventional wisdom on its head—one that's helping production facilities achieve what the majority are missing.

The Smart Manufacturing Pyramid: A Bottom-Up Framework

Think of smart manufacturing as a pyramid, not a shopping list. Each layer builds upon the previous one, creating a stable foundation for sustainable growth. Here's how it should look:

1. Human-Centered Foundation (People & Culture)

We think automation is primarily about replacing human labor, but actually, it's about augmenting human capabilities. The most successful smart factories start by preparing their workforce.

"The biggest mistake I see is companies investing in advanced technologies without first investing in their people," says Maria Chen, Manufacturing Innovation Director at a leading automotive plant. "When we implemented our smart factory initiative, we spent six months on workforce development before installing a single sensor."

This foundation includes:

- Skills assessment and development: Mapping existing skills against future needs

- Change management protocols: Structured approaches to help teams adapt

- Cross-functional collaboration: Breaking down departmental silos

- Technology champions: Identifying and empowering internal advocates

How does this look in practice? One medical device manufacturer I worked with created a "Digital Dojo"—a physical space where employees could experiment with new technologies in a low-stakes environment. This approach reduced resistance and accelerated adoption when they later implemented automated quality inspection systems.

2. Process Optimization & Standardization

Here's the thing about automation: it amplifies whatever process it touches. If your process is inefficient, automation will make it inefficiently faster.

"We had a client who wanted to automate their assembly line," recalls James Rodriguez, a manufacturing systems integrator I interviewed. "When we mapped their existing process, we found 27 unnecessary steps that would have been baked into the automated system. We helped them streamline first, then automate. The result was 43% higher throughput than their original automation plan."

Before implementing smart technologies, focus on:

- Value stream mapping: Identifying and eliminating waste

- Process standardization: Creating consistent, repeatable procedures

- Quality management systems: Establishing clear quality standards

- Maintenance protocols: Developing preventive maintenance schedules

A food processing plant I consulted for spent three months standardizing their changeover procedures before implementing automated changeover systems. The result? Changeover times decreased by 71%, compared to the 40% reduction projected from automation alone.

3. Data Infrastructure & Connectivity

We often think of data as an output of smart manufacturing, but actually, it's the essential input. Without proper data infrastructure, advanced analytics and AI have nothing to work with.

This layer includes:

- Sensor deployment: Strategic placement of basic sensors

- Network infrastructure: Reliable, secure connectivity

- Data storage solutions: Scalable systems for collecting and storing data

- Basic data governance: Protocols for data quality and management

"Start simple," advises Lisa Park, IoT Implementation Specialist. "I've seen companies try to capture everything at once and get overwhelmed. Begin with the most critical processes, establish reliable data collection, then expand."

One textile manufacturer I worked with started by simply monitoring machine uptime with basic sensors. This alone revealed utilization patterns that allowed them to increase production by 18% before implementing any advanced automation.

4. Analytics & Visibility

Once you have reliable data flowing, you can begin making it useful through:

- Real-time dashboards: Visual representations of key metrics

- Basic analytics: Identifying patterns and trends

- Performance tracking: Measuring against established KPIs

- Anomaly detection: Identifying deviations from normal operation

A chemical processing facility implemented simple analytics dashboards that made production data visible to operators. Within three months, they identified inefficiencies that had been invisible for years, leading to a 12% reduction in energy consumption—all before implementing any advanced automation.

5. Advanced Automation & Intelligence

Only after establishing these foundations should you implement advanced technologies like:

- Autonomous systems: Self-operating equipment and vehicles

- Advanced robotics: Flexible, adaptive robotic systems

- AI and machine learning: Predictive capabilities and optimization

- Digital twins: Virtual replicas for simulation and testing

"The companies that get the most from advanced automation are the ones who did the groundwork first," notes Michael Thompson, Manufacturing AI Specialist. "They're not using AI to figure out basic problems—they're using it to optimize already-solid processes."

Implementation Roadmap: Turning Framework into Reality

So how do we actually put this framework into practice? Let's break it down into actionable steps:

Phase 1: Assessment & Planning (1-3 months)

- Conduct a digital maturity assessment: Objectively evaluate your current state

- Identify value opportunities: Where will smart automation deliver the most impact?

- Develop skills matrix: Map current capabilities against future needs

- Create cross-functional team: Include operations, IT, engineering, and HR

- Establish baseline metrics: What will you measure to determine success?

Phase 2: Foundation Building (3-6 months)

- Launch workforce development program: Begin upskilling initiatives

- Optimize critical processes: Apply lean principles before automation

- Implement basic sensors: Start collecting data from key equipment

- Establish data infrastructure: Deploy networks and storage solutions

- Develop governance protocols: Create standards for data quality and security

Phase 3: Initial Implementation (6-12 months)

- Deploy visualization tools: Make data visible to operators and managers

- Implement basic analytics: Start identifying patterns and opportunities

- Pilot first automation project: Choose a high-value, lower-risk application

- Document lessons learned: Create knowledge base for future projects

- Celebrate early wins: Build momentum through visible successes

Phase 4: Scaling & Advancement (12+ months)

- Expand sensor network: Increase data collection breadth and depth

- Implement advanced analytics: Move from descriptive to predictive capabilities

- Deploy additional automation: Expand to other areas based on proven value

- Integrate systems: Connect previously siloed systems and data

- Continuously improve: Refine approach based on results

Common Pitfalls: What Derails Smart Manufacturing Initiatives

What about elsewhere? What are other factories getting wrong in their smart manufacturing journeys? Here are the pitfalls I see most frequently:

Technology-First Thinking

"We need to implement AI" is not a strategy. Starting with technology solutions instead of business problems leads to expensive systems that don't address actual needs.

Better approach: Start with the problem statement. "We need to reduce unplanned downtime by 30%" provides clear direction for technology selection.

Big Bang Implementation

Attempting to transform everything at once almost always fails. I've seen companies invest millions in comprehensive solutions that overwhelm their organization's ability to adapt.

Better approach: Start small, prove value, then scale. One automotive components manufacturer I worked with began with a single production line, perfected their approach, then expanded to others.

Neglecting Cybersecurity

As factories become more connected, they become more vulnerable. Cybersecurity cannot be an afterthought.

Better approach: Include cybersecurity experts from the beginning. Build security into your architecture, not on top of it.

Insufficient Executive Sponsorship

Without leadership commitment, smart manufacturing initiatives often stall when they encounter inevitable challenges.

Better approach: Secure executive sponsors who understand both the potential and the journey. Educate leadership on realistic timeframes and expected outcomes.

Industry-Specific Considerations

The framework remains consistent across industries, but implementation details vary significantly:

Discrete Manufacturing

For industries producing distinct items (automotive, electronics, machinery):

- Focus on flexible automation that can handle product variants

- Implement track-and-trace systems for component-level visibility

- Prioritize quality inspection automation for complex assemblies

Process Manufacturing

For continuous flow industries (food and beverage, chemicals, pharmaceuticals):

- Emphasize real-time process monitoring and control

- Implement advanced process analytical technology (PAT)

- Focus on predictive maintenance for critical equipment

High-Mix, Low-Volume Manufacturing

For custom or small-batch producers:

- Prioritize flexible automation systems that adapt quickly

- Implement digital work instructions and operator assistance

- Focus on rapid changeover capabilities and scheduling optimization

The ROI Question: Making the Business Case

"This all sounds great," you might be thinking, "but how do I justify the investment?" It's a fair question, and one that requires nuanced thinking.

We often calculate ROI based on direct labor savings, but actually, the most significant returns come from areas that are harder to quantify:

- Quality improvements: Reduction in defects and rework

- Asset utilization: Increased equipment effectiveness

- Inventory optimization: Reduced working capital requirements

- Energy efficiency: Lower utility costs

- Time-to-market: Faster product introduction

One aerospace components manufacturer I worked with struggled to justify their smart manufacturing initiative based on labor savings alone. When they expanded their analysis to include quality costs, inventory reduction, and improved on-time delivery, their projected ROI jumped from 18% to 47%.

The Future of Smart Manufacturing: 2024 and Beyond

Looking ahead, several trends are reshaping factory smart automation:

- Democratized technology: Advanced capabilities becoming accessible to mid-sized manufacturers

- Sustainability integration: Smart systems optimizing for environmental impact, not just efficiency

- Human-machine collaboration: Focus shifting from replacement to augmentation

- Edge computing: Processing moving closer to the point of data generation

- Composable architecture: Modular systems that can be reconfigured as needs change

"The factories that will thrive aren't just adopting new technologies," observes Dr. Sarah Williams, Manufacturing Futurist. "They're building adaptive systems that can evolve with changing market demands and technological capabilities."

Starting Your Smart Manufacturing Journey

So where do you begin? Based on my experience with dozens of manufacturing transformations, here are five steps you can take today:

- Assess your digital maturity: Honestly evaluate where you stand today

- Identify your biggest pain points: Where could smart automation deliver immediate value?

- Inventory your data: What are you already collecting, and what gaps exist?

- Evaluate your workforce readiness: Do you have the skills needed for transformation?

- Start small but think big: Begin with focused pilots that connect to a larger vision

Remember, smart manufacturing isn't a destination—it's a journey of continuous improvement and adaptation. The most successful manufacturers aren't necessarily those with the most advanced technology, but those who have built the organizational capability to continuously evolve.

Beyond the Technology: The Human Element

As we wrap up this exploration of smart manufacturing frameworks, I want to return to where we began: people. In our rush to implement new technologies, we sometimes forget that manufacturing has always been—and will always be—fundamentally human.

The smartest factories I've visited aren't just technically sophisticated; they're places where technology enhances human capability rather than replacing it. Where operators use data to make better decisions. Where engineers have time to innovate because routine tasks are automated. Where managers can focus on developing their teams rather than fighting fires.

What would your production facility look like if technology was deployed in service of your people, rather than the other way around? How might your approach to smart manufacturing change if you started with this question?

The future of manufacturing isn't about factories without people. It's about people with better tools. And building that future starts with getting the framework right.

What's your next step on the smart manufacturing journey? And more importantly, are you building from the bottom up, or still trying to start from the top?

Related articles

The Blueprint or the Gamble: Why a Clear Project Plan Is Your Greatest Asset

As a manager, you want successful outcomes. Discover why a vague project plan is a recipe for failure, while a detailed blueprint empowers your team, de-risks your investment, and guarantees measurable success. Learn to distinguish between a gamble and a guaranteed win.

Beyond the Black Box - Making Machine Learning Transparent and Trustworthy in Industry

Discover why explainability is crucial for ML adoption in critical industrial operations and how to build trust through transparency and clear communication.

Ready to get started with ML4Industry?

Discover how our machine learning solutions can help your business decode complex machine data and improve operational efficiency.

Get in touch